Reshaping the Paradigm: The Art of Learning by Doing

How do we learn to make ceramics? We can easily identify our skills, but how do we quantify our knowledge? Skill and knowledge are two entirely different entities with differing vocabularies, yet they are intimately entwined.

There are skill sets for every aspect of making ceramics, in whatever way and on which ever path we choose. We can spend a lifetime cultivating our craft and amassing the technical abilities necessary to make our work, yet still have only scratched the surface. Our knowledge may or may not increase in proportion to our skills. Over time, we find many different ways of working, methods of thinking, and systems of processing external visual images, and their synthesis becomes the impetus for our ceramic work.

I look back at my ceramic history and wonder how I learned what I think I know. As we learn more about what we do in ceramics, we modify the constants so they become more precise. There are back doors for solving any problem that may be outside of accepted knowledge or information. What I know to be true in ceramics is that while I think I know some things, there is more that I don't know. The search for knowledge, information , and problem-solving is a daily challenge and one that can be daunting. After forty years I still learn by doing. I still make mistakes. I like the axiom "Don't search for problems in ceramics. They will find you." Truer wisdom has never been more succinctly expressed! :

I have followed several different paths in my career. I started out, as many of us did after graduate school, with a teaching opportunity that allowed me the time to make and sell my work. Functional work was in high demand. Craft fairs and wholesale and retail shows abounded. It was the zenith of the American craft movement. While I had a modicum of skills for making and firing stoneware and porcelain, what I did not have were the tools to run a pottery-making business.

The markets were also in their infancy, as was my ability to use both the left and right sides of my brain. The artistic side was easy; learning and applying business skills was not.

There were few business models that could fit a pottery-making business. Equally, there were few role models to emulate. My education was university-based; both my BFA and MFA were focused on developing content and meaning within my work, not on debits, credits, bookkeeping, or how to sell what I made. While I learned many things during my years of higher education, there was no emphasis on how to make a living with these newly acquired skills. But I did have an increased knowledge base and a sense of inquiry that could be used to learn by doing - which was exactly what I did. My first production line of pottery was pretty basic: very solid forms with typical glazes, very representative of that time. My first attempt at book keeping was a green Wilson Jones 5-column sheet. The first price sheet was a primitive Xerox.

I would call a potential gallery or store and arrange an appointment. I would arrive with boxes of pottery all wrapped in newspaper, and in the middle of a busy business day would unpack a load of work, display it on the floor, and sell everything on the spot.

Terms were cash on delivery. It seemed to work, and it appeared to be a correct way to do business at that time. As my studio I in southeastern Pennsylvania developed, so did my skills at running a business. Everything was learned by doing, including my ideas for a product line. What would sell? What glazes would customers like? What would I like to make, to satisfy a growing list of stores and galleries waiting to buy my work? By trying out new designs, new glazes, new work cycles, new everything, I grew a business. Wholesale venues became more sophisticated. Pricelists and sales sheets became well designed I learned to extend credit. My business skills increased as did my knowledge base of how to make ware on a larger scale. While the success of Kaplan-JIuling Pottery was due to hard work by both my partner Jan and me, a significant part of these accomplishments reflected the times. The 1970s and '80s were lucrative times for artists and craftspeople. Yes, luck had a strong part in the success, as did the desire to be successful.

All this learning by doing was the result of handwork - m y hands, Jan's hands, our one assistant's hands - no assisted technologies. We learned that there was only so much we could produce ourselves, with our hands and without any help. Help came in the form of a Ratcliffe jigger machine imported from England. Integral to this rudimentary method of making multiples was plaster-work: molds, models, jigs, fixtures, templates, drawing, conceptualizing;

New tools and techniques – a new learning curve. The immediate result, of course, was an increase in production, but the bigger picture was an expanded knowledgebase that was all acquired through learning by doing. This early exploration of making multiples was the beginning of my future career as a ceramic designer: the merging of technology and toil with plaster and clay. It was the beginning of a paradigm shift in my thinking as a potter. So much of what I had made during the previous years was market-driven.

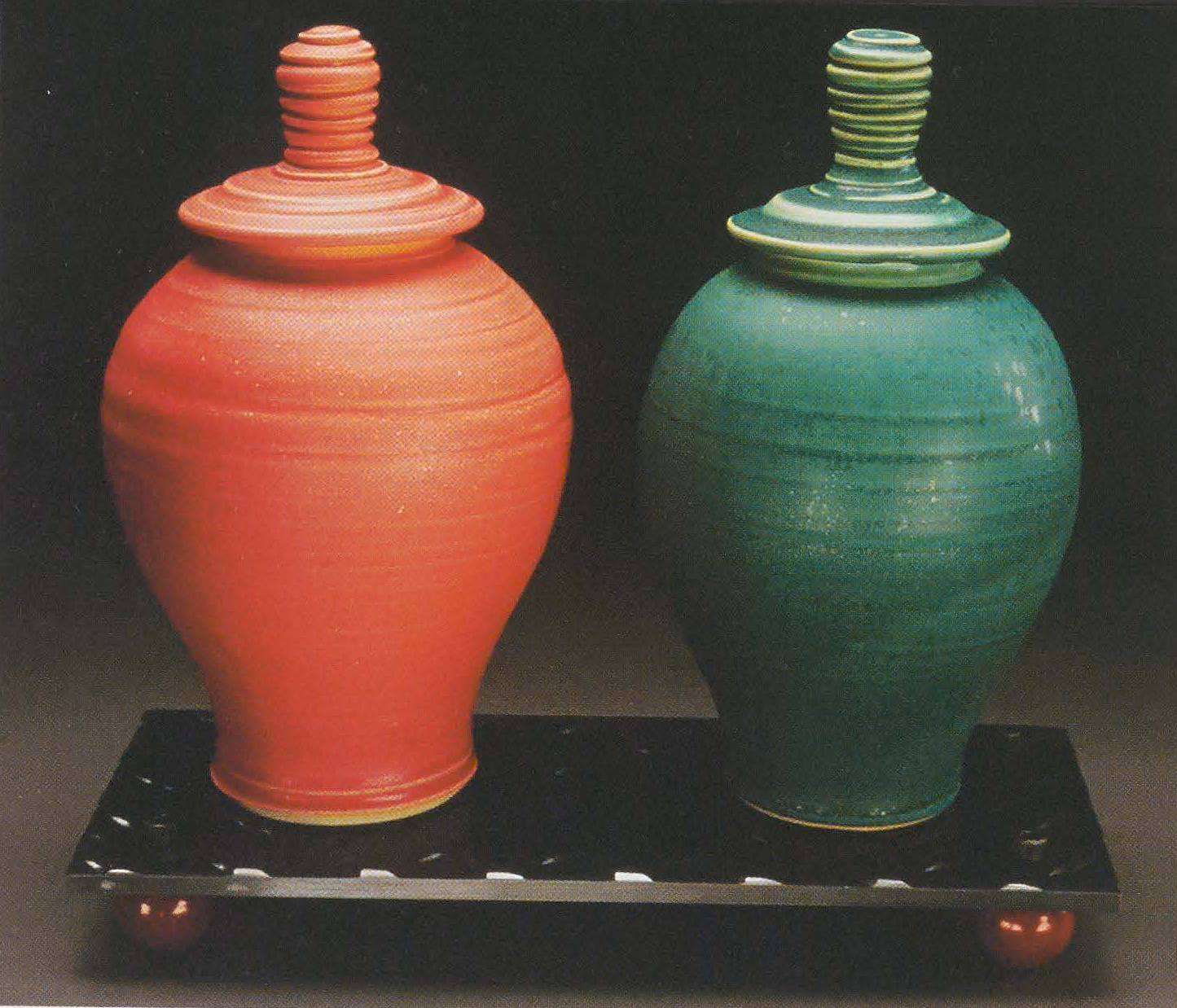

I was able to experiment with different designs, shapes, forms, glazes; all the work was wheel thrown and very much concerned with that process. Although ideas were evident in my pottery, there was little emphasis on the design process. Now I had an opportunity to redefine myself as an artist, potter, and craftsman, and perhaps most important, to define a new career path for myself as a ceramic designer. As a potter, I made pottery, vessels, objects, ascribed form and shape. What could I expect as a designer of these things? What could I expect as I merged them? My evolving knowledge base would again all be acquired by the process of learning by doing.

Working with plaster is to a great degree antithetical to forming a piece on the wheel or by hand-building. Understanding that plaster does not forgive and clay does is basic to the learning curve. The forgiving nature of clay allows us an easy remake; if it does not meet our expectations or visual criteria, we can simply make another one. Our learning requires more than just mastery of skills or a simple remaking of that piece. Ceramics in all its many forms is highly skill-intensive. We spend an inordinate amount of time learning these skills, often at the expense of critical thinking. Learning by doing requires assimilating our skills with our critical thinking in a non-linear, non-sequential way.

Perhaps a way of understanding this is to look at the two main materials that occupy my studio time. As a ceramic artist, my materials are clay and glaze. As a mold and model maker, my material is primarily plaster, but without the knowledge and use of clay, what I make in plaster would be useless. These two distinct and different materials, each requiring its own skills, vocabulary and technique, are interrelated. Another link between the two is a shared learning curve, the time and space necessary for understanding the complexities and subtleties of each. What we start with early in our education and involvement with clay is nowhere near what we end up with as our careers evolve and mature.

As I embarked on my new career as a moldmaker and ceramic designer, it was necessary to offer production capabilities to my clients .Here was the beginning of the perfect situation to merge my skills and knowledge as a production potter with those of a designer, to become more than just a manufacturer.

I could bring my aesthetic sensibilities to a small factory situation and develop work that had more substance, more style, more design.

Content was not even a consideration for my commercial clients; quality, timely delivery, and made in the United States at a reasonable price were more important. Much of the ceramic production business had moved offshore, and those domestic facilities still making pottery did not have any capacity for small runs beyond what they were already doing. There were no contract facilities that could provide complete start-to-finish capability.

The ceramics world is a small one; word of what I could offer to potters, artists, and other designers in the trade traveled quickly, bringing me inquiries about prototyping, samples, designing, and production of their work. The flood gates had indeed opened, and with this deluge came new opportunities to learn by doing.

I offered three ways of making work at my manufacturing facility in Steamboat Springs, Colorado: slipcasting, RAM (hydraulic) pressing and jiggering. All the tooling was made in-house: dies for the press, models, block,: : case, and production molds for casting and tooling. I refined my drawing and sketching skills and learned to develop my computer skills with Ashlar-Vellum software. Models were made from whatever material was appropriate:

clay, wood, RENSHAPE, plastic, and, of course, plaster. I learned by doing all the ways to make molds and models such as running/sledding plaster, cutting metal templates, turning plaster on a whirler (vertical tooling), or on a lathe (horizontal turning).These

are old-world skills and require considerable handwork to develop finished models. While there were a few helpful books available, mold- and model-making require specific processes for each situation. I created new techniques and ways of working. The work must be exact, and all work must be. Oversize to account for the multiple shrinkages of the clay as it moves through the manufacturing process. In the beginning I made many mistakes; some cost me a lot of money.

What I learned by doing many times over is that plaster is unforgiving and requires" design-based" thinking. While plaster does have a plastic state as it sets up and can be manipulated in any number of ways during this period, it does not exhibit the long-term plasticity that clay does, and requires planning beforehand. It has no memory or ability to be reformed. Plaster work of any kind is very similar to Asian cooking: considerable prep time followed by rapid stir-frying in a wok.

Decisions must be made long before the properly-weighed plaster and water are mixed together and then poured.

I usually start my plaster work with an idea that I can sketch on paper. By making a rudimentary drawing, I can get a feeling of shape, size, and perhaps volume. I may do a smaller or larger sketch and make some notes regarding details such as draft angles, parting lines, etc. I can also make a small three- dimensional maquette', using a cut-and-assembled paper pattern, that helps me see how the shape might exist in space. There are times when a technical drawing is needed; simple drafting skills and tools are usually enough to communicate the idea, but if necessary I can use the computer to further refine a two-dimensional drawing into a wire-frame model. From these drawings, enlarged to account for the shrinkage of the clay, I can make my templates, jigs, and fixtures. I also organize and outline the necessary steps to follow in logical sequence. There is no immediate making of the piece with plaster as there can be with plastic clay. For me, learning by doing has merged the many skills and knowledge of pottery-making with the tools and technology of working with plaster, to develop a new career and a new business. As a ceramic designer coming from a pottery background, I can easily visualize the work both in my mind's eye and on paper, and can also throw or hand-build it in clay before I commit to the lengthy and involved steps to create plaster tooling. By drawing first, the idea of what I wish to make begins to imprint in my head.

I can see it and then communicate it better not only to myself but also to my client. By designing first, I have a much better idea of what the form and its shape will be. By working as both designer and object-maker, I have reshaped my ceramic paradigm.

So where am I today? After more than fifteen years of working for others, making work in whose content I had little or no vested interest, I decided that it was time to rebuild my career as a ceramic artist. All we have as artists is our time, and it is a precious commodity. I closed my production facility and moved into a spacious live-work warehouse in the River North Arts District of Denver. I am in the process of renovating the building; a beautiful new exhibition space, Plinth Gallery, is finished and is a venue for exciting, interesting, and different approaches to the sculptural ceramic vessel, including my own. I still make some molds, models and prototypes of work for others, but only if it is of some interest to me. I am very fortunate to be able to follow my muse. And yes, I still learn by doing.